Panel Extrusions: The Ultimate Product for Creating Safe Structures

Introduction

Panel extrusions would be the latest innovation on earth of construction and building. These products are designed to create safe, strong, and structures that are durable. We will explore the advantages, safety, use, quality, innovation, and application of Lenwa panel extrusions.

Panel extrusions provide several benefits over other building materials. They are lightweight, strong, and resistant to corrosion and impact. They are also highly flexible, which renders them ideal for creating designs of all shapes and sizes. Lenwa panel framing extrusions are cost-effective, and they require minimal maintenance in comparison to other materials.

Safety is an consideration that are important it comes to building and construction. Lenwa panel aluminum t extrusions are designed to feel safe, with excellent fire-retardant properties. They are also resistant to temperatures which can be extreme weather. Panel extrusions are non-toxic, making them safe for use in homes, schools, along with other environments where safety is really a primary concern.

Panel extrusions can be used in a selection of applications, including roofing, cladding, facades, and partition walls. They are also ideal for producing sunscreens, louvers, and balustrades. Lenwa panel extrusion shapes can be used in residential, commercial, and buildings that are industrial. They are ideal for both interior and exterior use and they can be coupled with more building materials to create unique and customized designs.

Panel extrusions are simple to utilize and install. They may be cut to size using standard cutting, such as for instance saws and drills. Lenwa panel extrusions can also be easily welded and joined utilizing specialized techniques. They truly are easy to transport and keep, making them an ideal solution for projects that want quick and efficient installation.

commitment to personal service, we offer custom mold development aluminum profiles based on the drawings sketches you provide that ensure seamless integration with particular panel extrusions. vast array of precision services, like CNC milling and punching, as well as threading, and bends, us tailor every element of your design to the highest quality. provide a variety of customization options, from intricate designs precise specs.

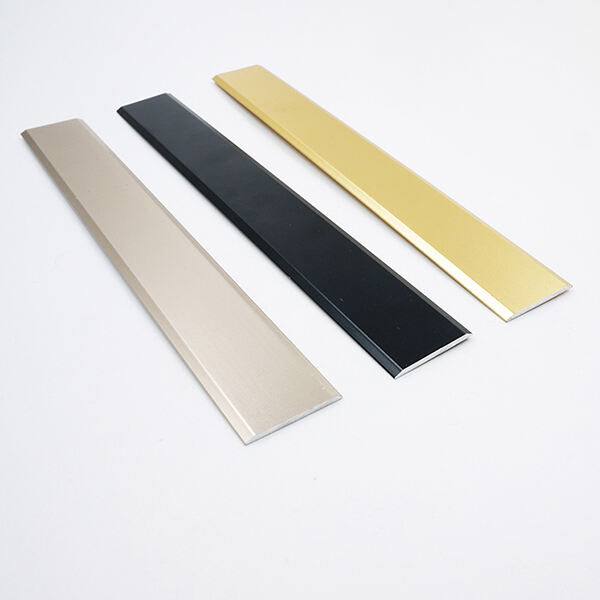

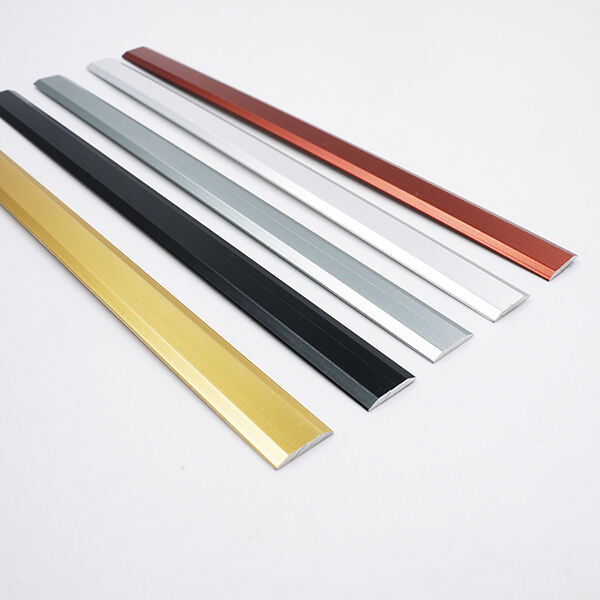

have more than 20 years of experience aluminum extrusion, surface treatment manufacturing aluminum profiles. expertise in aluminum panel extrusionsas well as surface finishing methods such as anodizing, powder coating and wood grain effect ensures highest quality and durability of every item.

diverse product range encompasses everything from architectural components home decoration profiles. We cater many different industries and uses. vast portfolio of products will assist you in finding the ideal profile to meet your needs, whether need panel extrusionsprofiles or bespoke solutions. With a commitment to quality and innovation constantly expand and enhance our product range in order to meet the needs of changing times of our customers.

have an unparalleled manufacturing infrastructure, which includes eight lines aluminum extrusions, 1 powder coating vertical line, dedicated wood panel extrusionsanodizing production lines. Additionally, we have three CNC machines numerous specially-designed equipment. This vast setup is guaranteed to provide precise and efficient production meets various requirements of our customers.

Panel extrusions are produced using the quality materials that are highest and production techniques. They are rigorously tested to ensure they meet markets guidelines for performance and safety. Quality assurance is an essential aspect of extrusion production, ensuring that clients receive items that are reliable, durable, and safe to use. You can count on getting excellent service and support from knowledgeable experts who can help you with any questions or concerns you may possibly have when you purchase Lenwa panel extrusions.

ONLINE

ONLINE