Aluminum Extrusion Profiles: Amazingly Strong and Safe.

Aluminum extrusion profiles are perfect inventions. They truly are designed and produced to meet a wide array of. They come in different designs, sizes, and applications that produce them perfect for various industries. We will see at the advantages, innovations, safety, use, and service of aluminum extrusion profiles.

Aluminum extrusion profiles have several advantages over other materials. They are lightweight, strong, and durable. They can be customized to match different shapes sizes, consequently they are simple to fabricate. The Lenwa aluminum extrusion profiles can be easily disassembled and assembled, making them suitable for items that require regular maintenance. Also, aluminum try environmentally friendly and that can be recycled, which makes it a sustainable material.

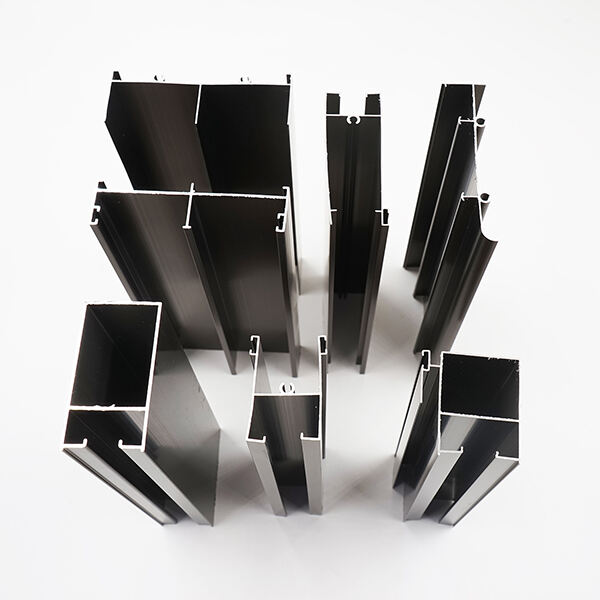

The development of aluminum extrusion profiles has seen many innovations the years. New technologies are making it feasible to supply custom designs and specialized profiles for particular applications. Tools like CAD (Computer-Aided Design) help manufacturers create unique profiles that meet certain requirements. The use of modern computer programs ensures the aluminum extrusion process along with the Lenwa aluminum channel extrusions is carried call at a controlled environment ensuring high-quality results. The extrusion process can also be along with other machining processes to generate parts with complex shapes and details.

Safety is essential, particularly in looking industries for heavy machinery and equipment. aluminum extrusion profiles are safer compared to other materials like steel. They do not rust, weaken or corrode, that could pose risks to equipment. Also, aluminum features a much lower density than steel, which reduces the weight of structures, making them less vulnerable to collapse. This makes aluminum extrusion profiles as well as Lenwa aluminum enclosure extrusions ideal for construction applications.

Aluminum extrusion profiles are versatile and can be properly used in a lot of industries, such as construction, automotive, and aerospace. They have been utilized in frames, enclosures, conveyors, as well as other structures. The profiles such as Lenwa custom aluminum extrusions may be designed to withstand harsh environments high temperatures and pressures. They also can be utilized in applications that want customization and precision, such as medical machines and scientific instruments.

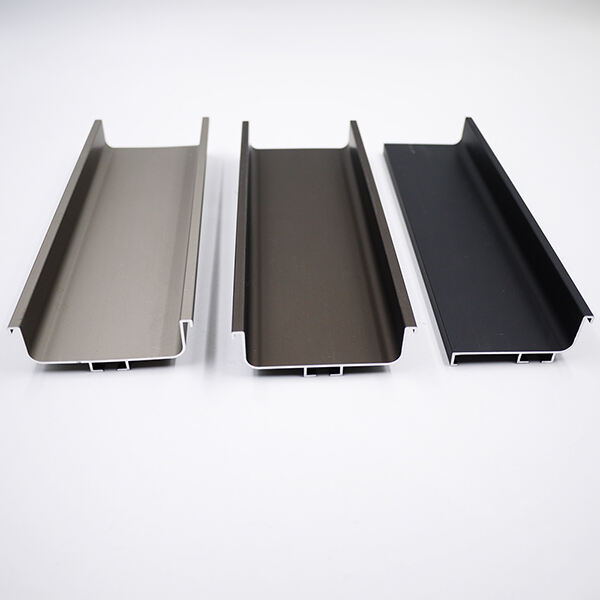

more than 20 years of experience aluminum extrusion surface treatment methodologies have aluminum extrusion profilesexpertise in creating aluminum profiles of top quality. expertise in aluminum extrusion and the techniques of surface finishing, such as powder coating, anodizing wood grain effects ensure the best quality and longevity of each product.

commitment personal service, can provide custom mold development for aluminum profiles based upon the drawings or sketches you provide, which ensures seamless integration with your specific requirements. extensive range of precision services, such as CNC milling and aluminum extrusion profiles, as well as threading, and bent, allows to customize every aspect your design to perfection. From intricate designs to exact specifications, we offer an array of options for customization to bring your vision to life using precision efficiency.

broad product portfolio includes everything from architectural components decorative profiles for homes. serve a wide range of different industries and uses. comprehensive portfolio will help you find the right profile for your project, regardless of whether you need standard profiles aluminum extrusion profilessolutions. We're dedicated to quality and innovation, as we continue to develop and improve our products to meet the evolving demands of our customers.

have an unparalleled manufacturing infrastructure, which includes eight lines aluminum extrusions, 1 powder coating vertical line, dedicated wood aluminum extrusion profilesanodizing production lines. Additionally, we have three CNC machines numerous specially-designed equipment. This vast setup is guaranteed to provide precise and efficient production meets various requirements of our customers.

Aluminum extrusion profiles is simple to utilize and will be manipulated to suit different applications. The first step using the profiles is always to design them using CAD software. The profile design is then delivered to the producer to produce a custom die the profile. The extrusion process like in aluminum extrusion shapes involves heating the aluminum billet and forcing it through the die to produce the profile. The profiles are then cut to size, finished, and assembled. They could be painted, anodized or brushed to enhance their aesthetic appeal and resistance.

Aluminum extrusion profiles can be purchased in a wide variety of, shapes, and applications. To make fully sure you get the most merchandise beneficial just likealuminum corner extrusion for the application, it is vital to function with a reputable manufacturer. Good providers have enjoy producing safe profiles and high-quality. Additionally they offer customization alternatives, turnaround times, fast and customer excellent care. They work to you to realize their needs and create profiles that meet your requirements.

Quality control is important when you look at the production of aluminum extrusion profiles. Good providers have strict quality control procedures that ensure the profiles meet industry standards. They design, fabricate, and test profiles to make sure they have been stronger, durable, and safe. In addition they use modern technology to do non-destructive assessment ensuring the profiles free from any defects.

ONLINE

ONLINE