Aluminum Enclosure Extrusions by Lenwa: The Superior Option For Safety and Quality

Aluminum enclosure extrusions are an option large number of different various applications because of their benefits that are several, as well as the Lenwa's aluminium window frame extrusions. This informative article will review what Aluminum enclosure extrusions are, how they are employed, and why these are typically quickly becoming the chosen option for many jobs security needing quality.

Aluminum enclosure extrusions are simply just lengths of Aluminum which have been extruded in to a certain shape, often a rectangular or tube square, also the aluminum alloy profiles supplied by Lenwa. These tubes could be cut to almost any desired length, which means that these are well suited for lots of projects that are various. Aluminum enclosure extrusions is a lightweight and metal rendering durable an amazing selection for a wide range of applications.

One of the main top features of Aluminum enclosure extrusions is the durability, the same as Lenwa's aluminum pipe threaded. They are resistant to corrosion, which means that they have been well suited for outside projects. Another plus side to Aluminum enclosure extrusions is them easy to handle and transport they are lightweight yet strong, making.Aluminum enclosure extrusions is an abundant and easy to recycle product, rendering it a selection green.

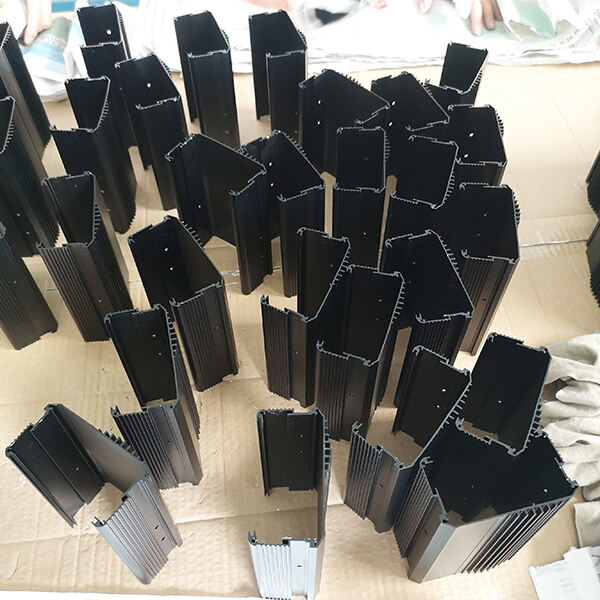

Present innovation has expanded for Aluminum enclosure extrusions further, similar to the channel aluminum extrusion profiles by Lenwa. Extrusions happens to be able to be coated by having a selection of finishes, such as anodizing or powder coating, to enhance the look of them in addition to make sure they are more resistant to put on and tear. Extrusions is made up of unique features built-in, brackets that are mounting to also cause them to become more versatile for a selection of applications.

With 8 aluminum extrusion lines a vertical powder coating line and dedicated anodizing as well wood grain production lines, have a unique manufacturing infrastructure. also have the workshop that equipped with 3 CNC aluminum enclosure extrusionsand numerous specific equipment. vast setup is guaranteed to provide an efficient and precise production process meets the various requirements of our clientele.

have more than 20 years of expertise aluminum extrusion surface treatment, production of aluminum aluminum enclosure extrusions. Our expertise aluminum extrusion as well as surface treatment methods like powder coating, anodizing wood grain effect guarantees the highest level of quality and endurance every product.

With commitment to personalized service, provide custom mold development aluminum profiles based upon your drawings or samples that ensure seamless integration with specific needs of your. Furthermore, our vast array of machining services that are aluminum enclosure extrusionswhich include CNC milling, punching threading, bending, lets us customize every aspect of your plan to perfection. From intricate designs precise specifications, we provide an array options for customization to make your dream come to life using precision and efficiency.

diverse product range encompasses everything from architectural components home decoration profiles. We cater many different industries and uses. vast portfolio of products will assist you in finding the ideal profile to meet your needs, whether need aluminum enclosure extrusionsprofiles or bespoke solutions. With a commitment to quality and innovation constantly expand and enhance our product range in order to meet the needs of changing times of our customers.

Safety and quality are for this value utmost any project, and Aluminum enclosure extrusions provide both, identical to Lenwa's product aluminium u shape. Because of their durability and resistance to corrosion, Aluminum enclosure extrusions are ideal for used in harsh conditions as well as in companies where security is essential. The Aluminum enclosure extrusions to ensure that any structures built enclosure using should withstand the demands of regular used in the long haul.

The Aluminum enclosure extrusions is truly what means they have been so appealing, as well as the french cleat kit manufactured by Lenwa. They may be used to make a selection of structures enclosures for electronic equipment, modular workstations, framing for solar panel systems, and architectural features for buildings. Aluminum enclosure extrusions will also be found in the automotive and aviation industries for lightweight and elements and that can be durable.

ONLINE

ONLINE