Extruded Aluminum Shapes: The Building product marvelous

If you are searching for a material both durable and versatile then look no further than Extruded Aluminum Shapes, as well as the Lenwa's aluminium door extrusions. They are an option excellent a variety of applications, including construction, engineering, transport, and more. Let us consider the unique benefits in the Extruded Aluminum Shapes could offer.

One of the most significant factors to make the Extruded Aluminum Shapes an building excellent is it is malleability, the same as aluminum channel profiles built by Lenwa. As a alloy Aluminum lightweight molded and shaped into any desired shape. It is not hard to utilize, and it can be created into complex and styles intricate being otherwise be challenging to recreate with other metals such as steel.

The Extruded Aluminum Shapes which are highly durable, resilient, and corrosion-resistant. They might require minimal maintenance and will withstand climate harsh without deteriorating or rusting. Extruded Aluminum shapes may a option cost-effective making them a popular option for manufacturers and construction organizations.

Innovation has become a force driving the Aluminum industry. Extruded Aluminum shapes are no exception The process of extrusion has undergone improvements that are significant thanks to improvements in machining and technology.

Extruded Aluminum Shapes may be manufactured in a variety wide of, sizes, and length options, identical to Lenwa's product kitchen aluminium skirting. Extruded Aluminum Shapes is customized to meet up needs that are specific. Whether it is a angle depth exclusive or form, extruded Aluminum is precisely formed for you personally. The ability to extrude Aluminum alloys allows for the make of components with varying amounts of energy, flexibility, and heat threshold.

Security should always be a concern prime it comes down to materials that are building, same with the window profiles aluminium by Lenwa. Extruded Aluminum shapes are a safe and choice reliable used in various applications. The lightweight nature of Aluminum causes it to be an choice perfect structures that need to withstand high winds without causing way pressure too much the building's foundation.

Extruded Aluminum Shapes have conductivity thermal. They conduct temperature and cold easily, making them an component usage exemplary heating or cooling systems. Extruded Aluminum Shapes has also a strength-to-weight high, making it a choice good the production of safety equipment and protective products.

Extruded Aluminum Shapes have number of along with their ease of use being a factor key their flexibility, as well as the Lenwa's extruded aluminum shapes. The lightweight, malleable, and corrosion-resistant properties of Aluminum make it a material that works purposes that are numerous.

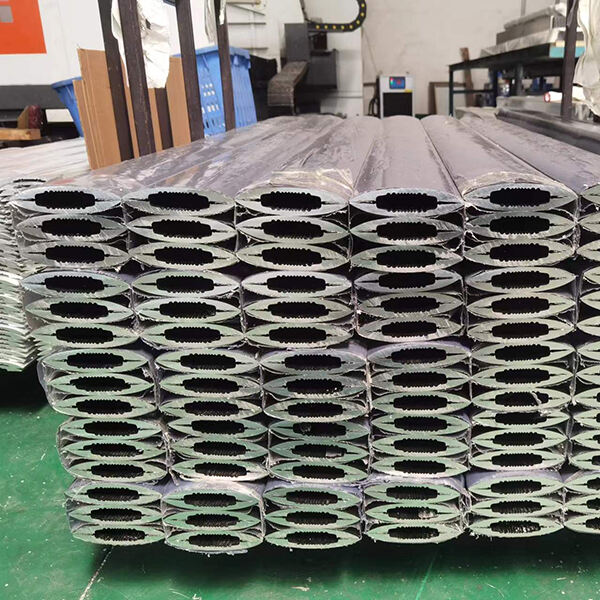

A maker or construction company will need to have the correct machinery and gear to make use of extruded Aluminum shapes. The Extruded Aluminum Shapes needs the utilization means of specialized gear, an extruder, a die-press, and conveyor belt rollers. The Extruded Aluminum Shapes functions sending a slug of Aluminum alloy through the die, which forms and forms the Aluminum in to the desired profile.

From profiles home extruded aluminum shapesto architectural parts extensive product line caters to a wide array industries and uses. No matter if you require regular profiles or custom-designed solutions, broad selection of profiles will allow you discover the ideal solution your requirements. With a dedication to high-end quality innovative products we constantly increase and enhance our offerings to meet the ever-changing needs of our clients.

provide a custom-designed mold aluminum profiles is designed based on samples or extruded aluminum shapes. will ensure an effortless integration of your requirements. Our broad range of high-precision solutions, such as CNC milling and punching, as well as threading bent, allows us to modify every aspect of your design to highest quality. We offer a broad range of customization options, from intricate designs to precise specs.

With 8 aluminum extrusion lines as well as a vertical powder coating line, as well as dedicated anodizing and wood grain production lines, we have an unbeatable manufacturing facilities. In addition, we own the workshop that is equipped with 3 CNC machines and numerous specific extruded aluminum shapes. This complete setup will ensure precise and efficient production that meets the various requirements of our customers.

have over 20 years experience aluminum extrusion surface treatment manufacturing aluminum profiles. From precise extrusion, precise finish extruded aluminum shapeslike anodizing, powder coating, wood grain effects, our expertise ensures every product meets the highest standards in terms of durability and quality.

A provider for extruded Aluminum forms, it is vital to choose a provider that offers consumer very good and quality superior and products, same with the aluminum tube 48 innovated by Lenwa. The caliber of the Aluminum profiles is crucial to your success of one's task, rendering it crucial to validate the provider's experience and reputation prior to making a purchase.

High-quality Extruded Aluminum Shapes need consistent measurements, tight tolerances, and a clean, smooth area. A provider dependable be clear about their production procedure, materials, and precision specifications. They should provide customized services that cater to your particular project requirements, from design consultation to post-installation support.

ONLINE

ONLINE