1. Introduction to Aluminium Section Channel

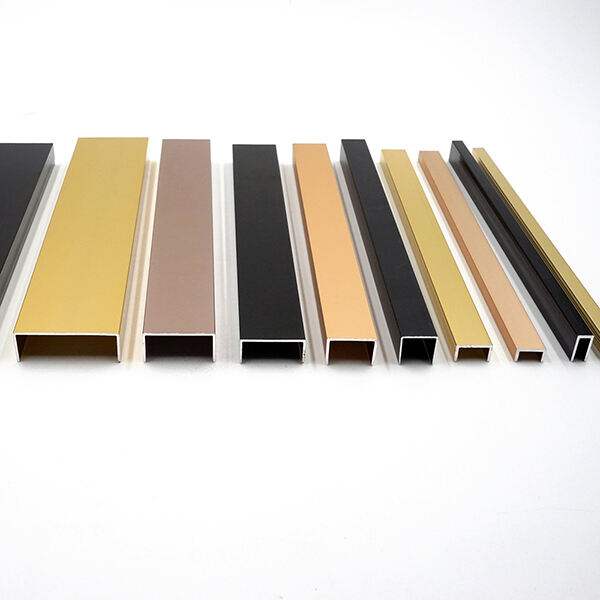

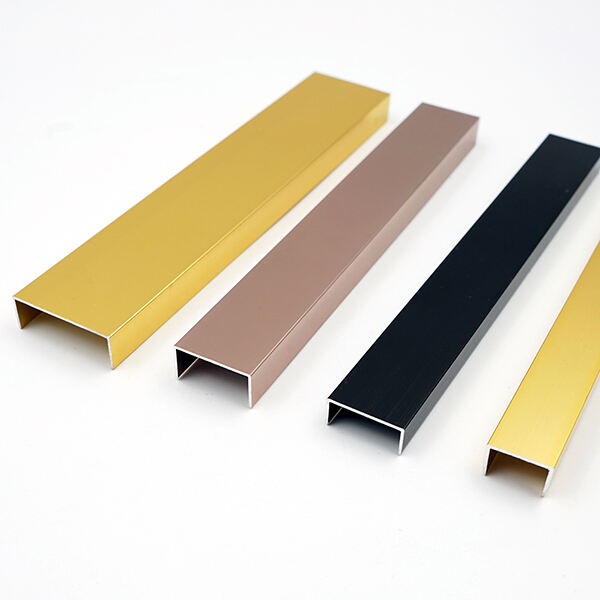

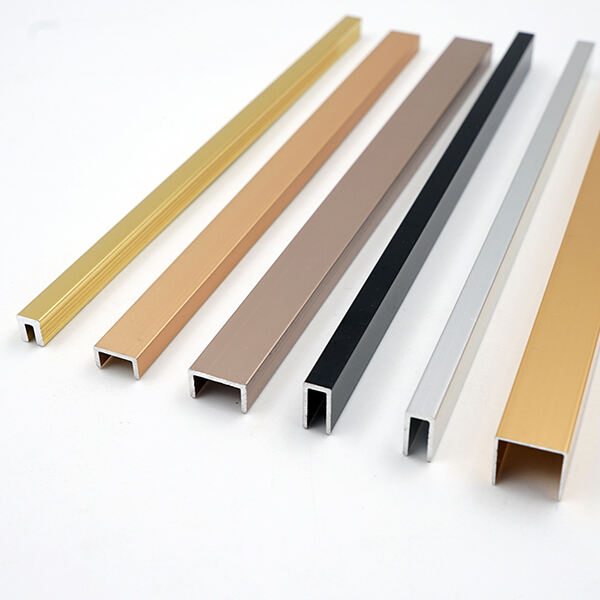

Aluminium section channels are a form of building employed product for various applications, such as construction, production, and inside design are a builders option popular of these durability, lightweight, and affordability. This aluminium channels from Lenwa from raw aluminium and it is processed into different shapes and sizes, including “U” shaped channel, “C” shaped channel, and custom channel profiles.

Aluminium section channels have several advantages over other building materials. Firstly, aluminium is a lightweight material makes it much simpler to manage during transport and installation. Secondly, aluminium is corrosion-resistant, which means it doesn’t rust, corrode, or fade easily, which provides it a full life long-lasting expectancy. Lastly, alu u channel from Lenwa is a sustainable option it really is 100% recyclable and will be reused without losing its properties.

Innovation is really important in the manufacturing procedure of aluminium section channels. The manufacturing latest technology ensures that aluminum channel extrusions from Lenwa have increased strength, durability, and precision to boost safety. In addition, the employment of computer-aided design (CAD) and computer numericalCNC control) machines provide more precise, efficient, and consistent production processes.

Furthermore, safety is a key consideration manufacturers. Aluminium section channels are made to be fireproof and non-toxic, making them safe for used in high-temperature applications. Additionally, the manufacturing process is stringent, resulting in a free item of burrs, sharp edges, along with other safety hazards.

Aluminium section channels have a wide assortment of across various companies. They've been found in construction, manufacturing, automotive, and interior design. One of the most common applications in construction where they truly are used for trusses, framework, facades, and more. In production, aluminium t channel from Lenwa are used for machine frames, conveyor belts, as well as other industrial applications. Also, in to the automotive industry can be used for frame and the body parts, and for interior design purposes.

our dedication to personal service,o ffer a custom mold development aluminum profiles based on your drawings or samples ensuring seamless integration to your particular requirements. wide range of precision services, like CNC milling and punching, aluminium section channelbending, lets us make every part your plan to perfection. From intricate designs to exact specifications, we offer complete customization options to create your vision using precision and efficiency.

more than 20 years of experience aluminum extrusion surface treatment methodologies have aluminium section channelexpertise in creating aluminum profiles of top quality. expertise in aluminum extrusion and the techniques of surface finishing, such as powder coating, anodizing wood grain effects ensure the best quality and longevity of each product.

have an unparalleled manufacturing infrastructure, includes 8 aluminum extrusions lines, 1 vertical line for powder coating as well as dedicated aluminium section channelgrain anodizing lines. Additionally, workshop houses three CNC machines alongside dozens of special machining equipment. complete setup allows for an efficient precise production process to meet the requirements of our many clients.

broad product portfolio includes everything from architectural components decorative profiles for homes. serve a wide range of different industries and uses. comprehensive portfolio will help you find the right profile for your project, regardless of whether you need standard profiles aluminium section channelsolutions. We're dedicated to quality and innovation, as we continue to develop and improve our products to meet the evolving demands of our customers.

ONLINE

ONLINE