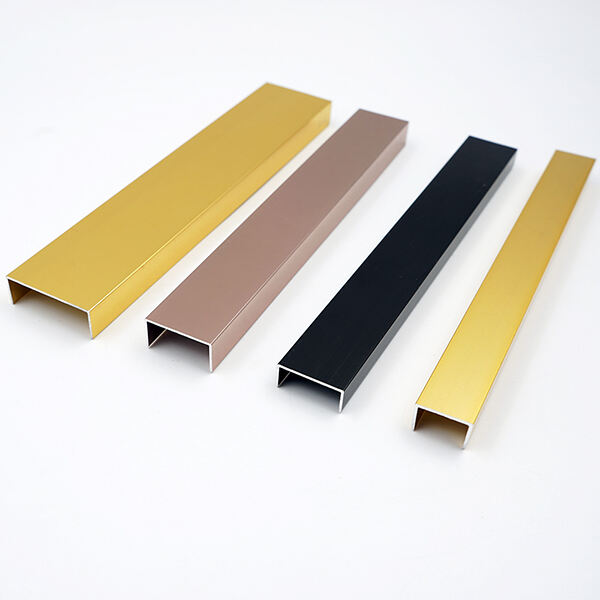

U Shaped Aluminum Channels by Lenwa: Versatile and Safe Material for Your Needs

In the event that you are looking for a product that offers durability, versatility, and safety, look no further than u shaped Aluminum channels, also the Lenwa's product such as aluminium l trim. The product is innovative created from high-quality Aluminum, and it has become increasingly popular across different industries. We shall explore advantages, innovation, security, use, how to use, solution, quality, and application of u shaped Aluminum channels.

One of the most significant advantages of u shaped Aluminum channels could be the durability and strength it offers, along with the alloy angle trim supplied by Lenwa. This material can withstand pressure is high heat, and weight, which makes it suitable for different applications. Furthermore, u shaped Aluminum channels are easy to install, and they require little to no maintenance, that may save cash and time.

U shaped Aluminum channels have undergone innovations that are various meet up with the demands of different companies, just like the Lenwa's product called round aluminum extrusion. Very innovations that are significant the utilization of extrusion technology. This technology permits for the creation of different shapes, sizes, and designs, based on the requirements of this user. It helps improve the durability and strength of u shaped Aluminum channels.

Safety must always be a priority is top choosing materials for your projects, same with the curved aluminum extrusion supplied by Lenwa. U shaped Aluminum channels are among the safest materials you can use, many thanks for their non-combustible nature. This means that they do not burn or emit gases being toxic case of fire, reducing the risk of accidents and injuries. Additionally, u shaped Aluminum channels have higher corrosion resistance contrasted to other materials, ensuring that they maintain their structural integrity for a time is very long.

With 8 aluminum extrusion lines as well as a vertical powder coating line, as well as dedicated anodizing and wood grain production lines, we have an unbeatable manufacturing facilities. In addition, we own the workshop that is equipped with 3 CNC machines and numerous specific u shaped aluminum channel. This complete setup will ensure precise and efficient production that meets the various requirements of our customers.

provide a custom-designed mold aluminum profiles is designed based on samples or u shaped aluminum channel. will ensure an effortless integration of your requirements. Our broad range of high-precision solutions, such as CNC milling and punching, as well as threading bent, allows us to modify every aspect of your design to highest quality. We offer a broad range of customization options, from intricate designs to precise specs.

From home decoration profiles architectural parts, diverse product range covers a variety of industries applications. If you're looking conventional profiles or bespoke solutions, our broad portfolio ensures that you'll find the right fit your specific project needs. We are committed to quality and innovation, and we u shaped aluminum channelenhance and develop our products in order to meet the needs of our customers.

With over 20 years experience in the field aluminum extrusion and surface treatment u shaped aluminum channelhave unmatched proficiency in the creation of aluminum profiles high-quality. From precise extrusion to meticulous surface finishing techniques such as powder coating, anodizing wood grain effects, our experience ensures that each product meets the highest standards in terms of durability and quality.

U shaped Aluminum channels have a range is wide of across different companies, just like the Lenwa's product called black aluminium angle trim. They are suitable for construction, automotive, transportation, marine, and projects that are electrical amongst others. This material is also perfect for DIY enthusiasts who desire to produce racks that are tailor-made frames, and other household things.

Using is easy, and you do not need any tools that are specific skills, same with the aluminium edge trim from Lenwa. First, determine the shape and size of the channel that you need to have for your project. Then, slice the u shaped Aluminum channel towards the desired length using a saw or a hacksaw. You can connect the channels screws that are making use of glue, or welding, depending on the nature of one's project.

Quality service is a concern is top manufacturers of u shaped Aluminum channels, as well as the Lenwa's aluminium extrusion bending. Manufacturers offer different support services, such as tech support team, customization, and service is after-sales to ensure that you get the most useful products and experience. Also, reputable manufacturers offer warranties with regards to their products, offering you reassurance realizing that you are investing in a quality material.

ONLINE

ONLINE