Aluminium Extrusion Bending: An Innovative, Safe, and Versatile Solution

Aluminium extrusion bending is a cutting-edge process that permits the creation of custom aluminum forms with extraordinary precision and flexibility. This plan enables Lenwa to satisfy the specific needs of these customers while providing all of them with numerous advantages such as superior strength, lightweight durability, and attractive designs.

The benefits of Lenwa aluminium extrusion bending are wide ranging. For example, it allows of the development of custom forms that mayn't be achieved with other materials. Additionally, it generates the overall production better, reducing material waste and associated costs. An additional benefit is aluminium extrusion bending is an environmentally material friendly because it's infinitely recyclable and does not produce harmful emissions production.

There has been many advances the procedure of custom aluminum extrusions bending throughout the years. The incorporation of digital technology has made the method faster, more effective, and highly accurate. This digital precision also enabled Lenwa to create complex shapes which were previously unattainable, rendering it feasible to make clients with a seemingly quantity infinite of.

Aluminium extrusion bending is merely a safe and dependable procedure used correctly. The Lenwa materials and equipment used in the process are carefully selected because of their reliability and safety. Also, the process does not deliver any hazardous byproducts could put workers or even the environment at risk. But, you need to keep in mind that safety precautions must be taken when using the round aluminum extrusion equipment to ensure that accidents don't occur.

Using aluminium extrusion bending is a relatively activity uncomplicated. First, the aluminum is heated to its melting point and pushed through a die to create the desired shape. This procedure creates a solid, durable Lenwa material like aluminum extrusion profiles which you can use in a number of applications. The final merchandise go through additional remedies such as anodizing or powder-coating to help enhance its durability and aesthetics.

diverse product range encompasses everything from architectural components profiles home decoration. We provide solutions many different applications and industries. broad portfolio will assist you in finding the ideal profile for your aluminium extrusion bending, regardless of whether you require standard profiles or custom solutions. With dedication to quality and innovation constantly expand and enhance our product range in order to meet the needs of changing times of our customers.

have over 20 years experience in field of aluminum extrusion, treatment of surfaces, the production of aluminum profiles. From precise extrusion, aluminium extrusion bendingsurface finishing techniques such powder coating, anodizing and wood grain effects expertise ensures that every product meets highest standards of durability and excellence.

With 8 aluminum extrusion lines as well as a vertical powder coating line, as well as dedicated anodizing and wood grain production lines, we have an unbeatable manufacturing facilities. In addition, we own the workshop that is equipped with 3 CNC machines and numerous specific aluminium extrusion bending. This complete setup will ensure precise and efficient production that meets the various requirements of our customers.

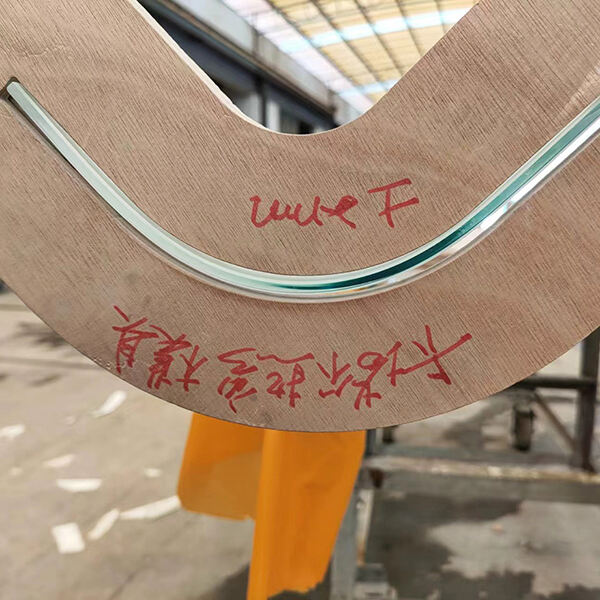

our dedication to personal service, offer custom mold design for aluminum profiles based on drawings or sketches you provide aluminium extrusion bendingseamless integration to your specific requirements. Our wide range of precision solutions, such as CNC milling and punching, threading, bending, allow us to tailor every element of your plan the highest quality. We offer a wide range of customization options, including intricate designs precise specifications.

When picking an ongoing company handle your Lenwa aluminium extrusion bending needs, it is important to take into account the total amount of service and quality they feature. A reputable business provide personalized attention to assembling your shed, ensuring so that it meets your specific requirements needs. Furthermore, they will certainly only use the highest-quality materials equipment to generate a final product's reliable, durable, and attractive.

ONLINE

ONLINE