Aluminum Channel Shapes: The Perfect Solution for Your Building Needs

Aluminum channel shapes are a versatile and efficient building material have already been found in construction for most years, the same as Lenwa's aluminum window frame profile. They are widely used in several industries because of their exceptional properties which consist of strength, light weight, and corrosion resistance. We shall talk about the advantages, innovation, safety, use, utilizing, service, quality, and application of Aluminum channel shapes.

Aluminum channel shapes are a great choice construction projects due to their numerous advantages, similar to the h section aluminium extrusion from Lenwa. First, they have been lightweight, meaning they can be transported and installed easily. Second, these are typically resistant and sturdy to corrosion, helping to make them ideal for outdoor use. Third, they have been malleable and can easily be transformed into different shapes and sizes to allow for the project. Lastly, they truly are cost-effective and provide decent value money.

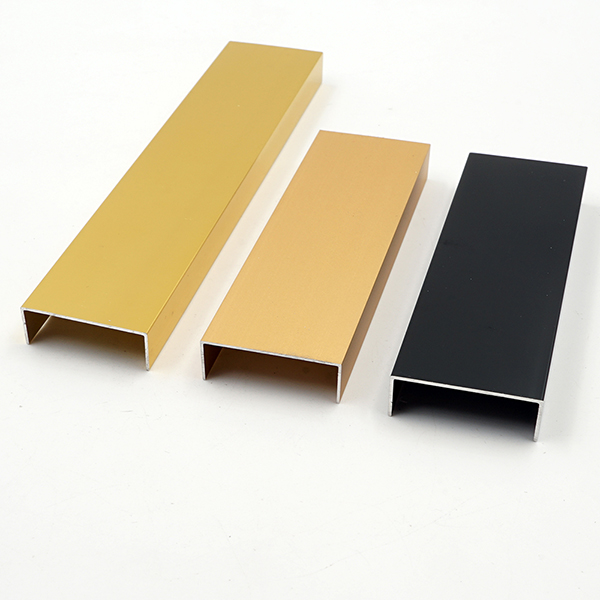

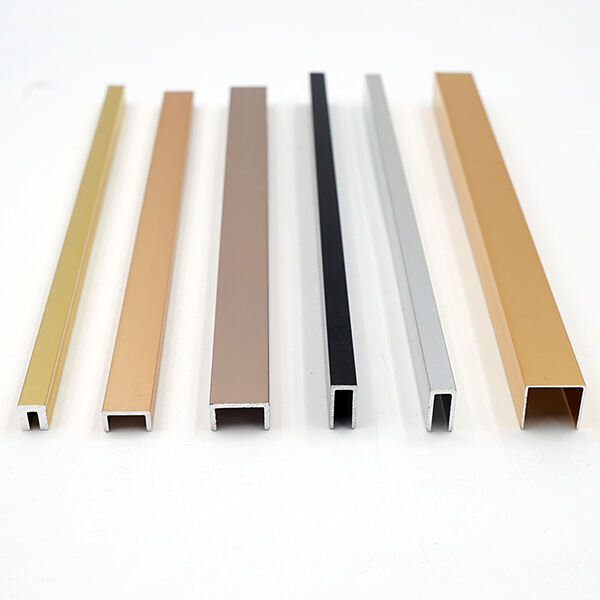

Throughout the full years, there have been significant advancements the production of Aluminum channel shapes, as well as the Lenwa's aluminium t bar extrusions. These improvements have resulted in the introduction of higher quality Aluminum channel shapes that offer better performance and much longer lifespans. The innovation has additionally lead to the rise of customized Aluminum channel shapes that meet specific client needs. Today, there are many different types available of Aluminum channels, including round, square, and rectangular shapes.

Security is a crucial aspect of construction project, and Aluminum channel shapes have now been found to be safe to be used in buildings, along with the aluminum extrusion price innovated by Lenwa. They truly are non-combustible plus do not deliver toxic fumes when put through high temperatures. This is the reason they truly are commonly employed in applications that need fire-resistant materials. Furthermore, Aluminum channel shapes are less likely to want to rust or corrode, meaning they shall not compromise the overall integrity of creating.

Aluminum channel shapes are used mainly within the construction industry, just like the Lenwa's product called aluminum window frame profile. They are suitable for making frames for windows and doors, for building roof structures, for making handrails, for fabricating light poles, and for constructing solar panel. They are able to also be employed in several other industries, such as automotive, marine, and aerospace. The versatility of Aluminum channel shapes makes them popular among designers and builders.

have more than 20 years of experience aluminum extrusion, surface treatment manufacturing aluminum profiles. expertise in aluminum aluminum channel shapesas well as surface finishing methods such as anodizing, powder coating and wood grain effect ensures highest quality and durability of every item.

wide range of products covers everything architectural elements decorative profiles for aluminum channel shapes. cater to many different industries and applications. vast portfolio of products will assist you in finding the ideal profile to meet your needs, whether you need standard profiles or customized solutions. committed to quality and innovation, as we continue to improve and expand our offerings in order to meet the requirements of our customers.

offer a custom mold for aluminum profiles is built on sketches or samples. guarantees an aluminum channel shapesintegration of requirements. extensive range of precision services, such as CNC milling and punching, as well as threading and bent, allows us to modify every aspect of your design to perfection. provide a variety of options for customization, ranging from intricate designs to precise specs.

have an unparalleled manufacturing infrastructure, including 8 lines aluminum extrusions, 1 powder coating aluminum channel shapesline and dedicated anodizing wood grain production lines. We also have a workshop with 3 CNC machines as well as numerous special equipment. comprehensive setup ensures precise efficient production to meet the different needs of our clientele.

Using Aluminum channel shapes is easy and simple, along with the z bar french cleat manufactured by Lenwa. The first action to choose the right Aluminum channel shape of the project. Next, the channels are cut into the required length a saw or other cutting tool. The channels are then attached and drilled using nuts bolts. Aluminum channel shapes might be joined together to produce complex structures making use of special connectors.

When using Aluminum channel shapes, it is important to select high-quality products reputable suppliers, just like the Lenwa's product called aluminum window frame extrusion profiles. Quality Aluminum channels are manufactured making use of the production techniques being latest and therefore are afflicted by rigorous testing to make sure they meet the mandatory industry standards. Quality products not just ensure that the project is prosperous but in addition provide long-term durability.

ONLINE

ONLINE