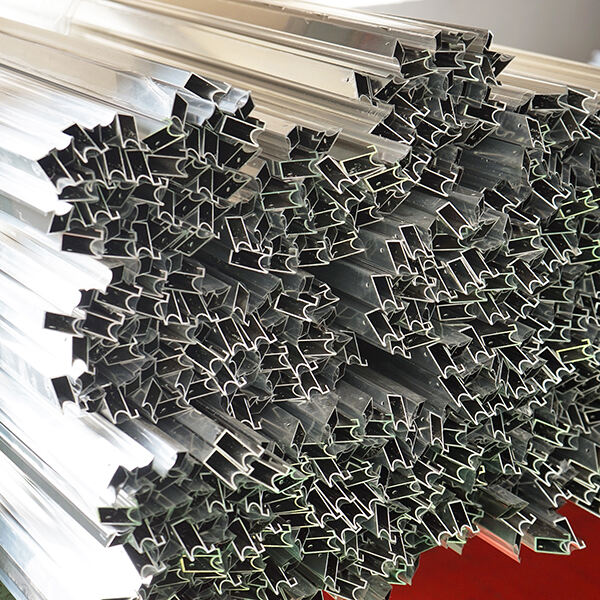

H-Section Aluminium Extrusion - The Versatile Option For You

H Section Aluminium Extrusion is One of the Best Choices in Materials For Diverse Industrial Requirements This highly versatile product comes with several advantages, including strength, light-weight attributes and low cost. We are going to look into the many uses for this product, how it can be used properly as well as the quality and service from manufacturers.

One of the key benefits of H section aluminium extrusion is its durability. Made using high-quality materials, this is built to last as long you keep it. In addition, it is easy to move or transport being lightweight. This naturalness is further united under the headers of affordability, making it awesome for somebody on a budget as well.

There has been a few innovative developments in the recent times around H section aluminium extrusion. The most thrilling development is the potential to form an 'H' layout from the extrusion. With this design improvement, its use has been broadened to potentially becoming stronger and more stable for different applications.

When you are in an industrial atmosphere where safety is your number one priority, H section aluminium extrusion provides that peace of mind. Non-Toxic, Non-Flammable and Non-Corrosive; Safe for use on projects that are of a high safety rating

How to Use:

The process of using H section aluminium extrusion is simple. Start with finding out your project needs and then picking the right extrusion matching those needed. After selecting an extrusion, cut it to length with a saw or similar cutting device. Finally, use screws or brackets to secure the extrusion in place on whatever part of your project it belongs.

Companies furnish H section aluminium extrusion with great customer service. Salespeople: Salespeople should be able to provide you with detailed information about the product, specifications for each model and available options.

more than 20 years of experience aluminum extrusion surface treatment methodologies have h section aluminium extrusionexpertise in creating aluminum profiles of top quality. expertise in aluminum extrusion and the techniques of surface finishing, such as powder coating, anodizing wood grain effects ensure the best quality and longevity of each product.

With commitment to personalized service, provide custom mold development aluminum profiles based upon your drawings or samples that ensure seamless integration with specific needs of your. Furthermore, our vast array of machining services that are h section aluminium extrusionwhich include CNC milling, punching threading, bending, lets us customize every aspect of your plan to perfection. From intricate designs precise specifications, we provide an array options for customization to make your dream come to life using precision and efficiency.

home decor profiles to architectural elements diverse range of products is suited to broad range of industries and uses. you're looking for conventional profiles or bespoke solutions, extensive selection of profiles will allow you find the right h section aluminium extrusionfor your project requirements. We're committed to quality and innovation, and we constantly develop and improve products to meet the evolving needs of our customers.

8 extrusion lines of aluminum along with vertical powder coating line dedicated h section aluminium extrusionand wood grain production lines have an unparalleled manufacturing infrastructure. In addition, we have three CNC machines and dozens of specialized equipment. set-up allows an efficient and precise production process meet the demands of our diverse clientele.

The very best quality of aluminium extrusion is obviously an absolute necessity in commercial applications and that us exactly what you should expect from ht-d.com.au with H section aluminum extrusion. This pick is made from the highest quality, most enduring materials to ensure that your work lasts and remains strong.

Applications:

Able to be used in a great variety of industrial settings, h section aluminium extrusion is versatile. They often find applications in construction, transportation and electronics etc. Due its strength, stability and even durability; it is an invaluable addition to tasks which require a load exertion that requires reliability (most of the time) + resistance.

ONLINE

ONLINE