Introduction: C channel aluminum extrusion is a kind of steel which has been trusted across companies. This informative article delves in to the features of aluminum extrusion, innovations which were manufactured in the industry, exactly how it can be utilized, in addition to ongoing services associated with it. The Lenwa c channel aluminum extrusion supplies a renewable and durable option when making goods.

The aluminum extrusion procedure offers importance which can be many. Initially, aluminum was lightweight in comparison with other products, making it simple to transfer, handle, and install. Furthermore, it is corrosion-resistant, that makes it a information and it’s great outdoor usage. Lenwa aluminum profile channel can also be malleable, meaning that it may be shaped into different forms, thus giving producers versatility in their designs. And also this makes it easy to customize for various applications. Aluminium are recyclable, and this makes it a information this is certainly best eco aware industries.

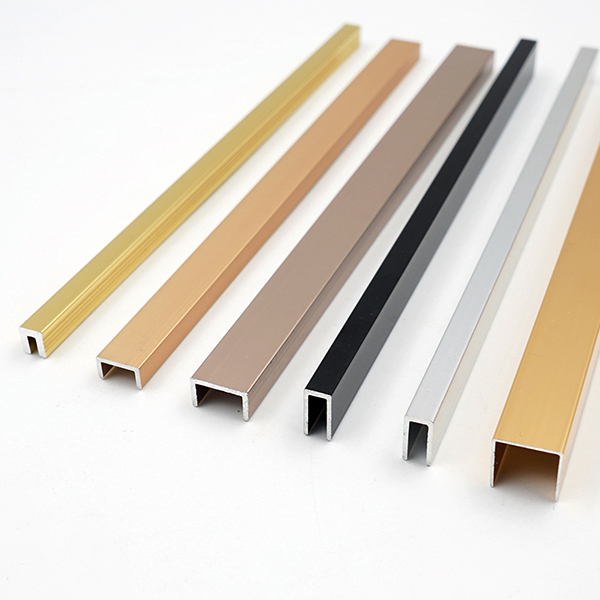

Innovation possess changed the aluminum markets, especially in manufacturing of c channel aluminum extrusion. Brands can acquire various forms associated with the profile aluminum extrusion through different manufacturing processes such as Hot extrusion, Powder layer or Anodizing. Improvements in tech have let brands to extrude smaller, more shapes which are complex which advances the variety of design and programs available. Lenwa channel aluminum extrusion profiles helps meet up with the market demand for high-quality, revolutionary, and items that were lightweight.

Protection is a consideration and it’s important manufacturing of any items, sufficient reason for C channel aluminum extrusion, there is absolutely no exemption. Safety begins with production and stops with all the product which was last. Lenwa Aluminum is non-combustible, and it’s information and it’s great it doesn’t burn off, unlike other products. In the eventuality of a fire outbreak, aluminum products wouldn't normally subscribe to the spread for the fire.

C channel aluminum extrusions need an range and it’s immensely diverse of compliment of their properties and characteristics. Its used in industries such as for instance structure, defense, automotive, electronics, building, and aerospace, just to mention a few. The Lenwa aluminum channel extrusions are used for making equipment such as frames, conveyor devices, fences, house windows, doors, greenhouses, light poles, partitions, and enclosures which can be electronic amongst others. The usefulness of aluminum extrusion means it has solutions which are practical numerous companies.

our dedication to personal service,o ffer a custom mold development aluminum profiles based on your drawings or samples ensuring seamless integration to your particular requirements. wide range of precision services, like CNC milling and punching, c channel aluminum extrusionbending, lets us make every part your plan to perfection. From intricate designs to exact specifications, we offer complete customization options to create your vision using precision and efficiency.

With more than 20 years dedicated experience aluminum extrusion as well as techniques surface treatment We are able offer unmatched expertise in c channel aluminum extrusionaluminum profiles of superior quality. From precise extrusion meticulous finish techniques like anodizing, powder coating, and wood grain effects, experience ensures that each product meets the highest standards of excellence and durability.

With 8 aluminum extrusion lines as well as a vertical powder coating line, as well as dedicated anodizing and wood grain production lines, we have an unbeatable manufacturing facilities. In addition, we own the workshop that is equipped with 3 CNC machines and numerous specific c channel aluminum extrusion. This complete setup will ensure precise and efficient production that meets the various requirements of our customers.

From profiles home c channel aluminum extrusionto architectural parts extensive product line caters to a wide array industries and uses. No matter if you require regular profiles or custom-designed solutions, broad selection of profiles will allow you discover the ideal solution your requirements. With a dedication to high-end quality innovative products we constantly increase and enhance our offerings to meet the ever-changing needs of our clients.

To make use of Lenwa channel this is certainly c extrusion, you'll need an aluminum extrusion device. Aluminum extrusion devices tend to be specifically made to profile the metal by hydraulic or stress this is certainly technical. The aluminum billet is heated it can be extruded effortlessly until it hits a heat where. The molten aluminum is required by way of a die, resulting in the desired model of the channel aluminum extrusion and it’s c. After shaping, there are many how to apply the final finish on the aluminum this is certainly extruded. The most popular among these procedures incorporate anodizing, painting, dust layer if not combining some of these processes by way of a finishing process that are mechanical.

High quality is definitely an aspect and it’s crucial of channel aluminum extrusion. Aluminum extrusions are made to lengths being particular tolerances. Through the production process, quality control inspections is done to make sure that the product this is certainly finished to your considering standards. Utilizing the Lenwa extruded aluminium channel technologies and it’s advanced on the market nowadays, high quality control inspections become performed if you use machines. Firms whom concentrate on aluminum extrusion are known to have a system this is certainly big of processes to make sure client satisfaction and confidence.

ONLINE

ONLINE