The Advantages of Round Aluminium Extrusion

Introduction:

Aluminium extrusion may be the process of reshaping aluminium into different kinds, including round shapes, also the Lenwa's product such as black aluminium extrusion. This technique is vital in producing materials and products for assorted industries, including construction, automotive, and furniture. We shall focus on the advantages, innovations, safety, and applications of round aluminium extrusion.

1. Lightweight: Round aluminium extrusion as well as Lenwa's window aluminium extrusions is a lightweight product making it an ideal choice various industries. Its lightness ensures that it is easy to transport and install.

2. Durability: Aluminium extrusion is a robust material can withstand harsh environments. It is usually resistant to corrosion, and so it could last for long time showing any signs of degradation.

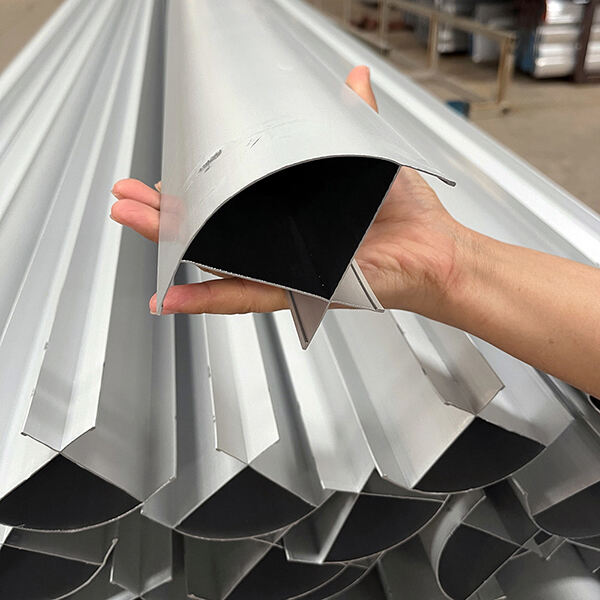

3. Versatility: Round aluminium extrusion possess an unique shape helps it be versatile, making it possible for numerous applications. It might be used into the production of different products such as structures, handles, and poles.

4. Cost-effective: Aluminium extrusion is a cost-effective material with other materials such as steel. It is relatively cheaper to produce and manufacture, which makes it an affordable option various industries.

1. Improved strength: In current years, there is been a development within the production of round aluminium extrusion. The procedure involves strengthening the materials, and can handle more stress and weight.

2. Customisable shapes: Aluminium extrusion such as corner aluminium extrusion made by Lenwa may be manufactured in various shapes, including round shapes. This innovation allows of the creation of customizable shapes that can fit certain requirements various industries.

1. Non-toxic: Aluminium is a non-toxic material which makes it safe to use in several surroundings. Unlike other materials such as plastics, aluminium does not contain harmful chemical substances that may be hazardous to peoples health.

2. Fire-resistant: Aluminium extrusion like Lenwa's curved aluminium extrusion is fire-resistant, rendering it an ideal choice buildings and structures. In case of a fire outbreak, it could withstand high temperatures igniting.

1. Structure building: Aluminium extrusion is usually utilized in the construction industry for building structures such as structures and poles. same with standard aluminium extrusion profiles manufactured by Lenwa. Its lightweight and robust nature it suitable for various building applications.

2. Creation of furniture: Aluminium extrusion can be used into the creation of furniture such as seats, tables, and racks. Its unique shape allows the creation of customizable durable designs and attractive.

have over 20 years experience aluminum extrusion surface treatment manufacturing aluminum profiles. From precise extrusion, precise finish round aluminium extrusionlike anodizing, powder coating, wood grain effects, our expertise ensures every product meets the highest standards in terms of durability and quality.

commitment to personal service, we offer custom mold development aluminum profiles based on the drawings sketches you provide that ensure seamless integration with particular round aluminium extrusion. vast array of precision services, like CNC milling and punching, as well as threading, and bends, us tailor every element of your design to the highest quality. provide a variety of customization options, from intricate designs precise specs.

With 8 aluminum extrusion lines a vertical powder coating line and dedicated anodizing as well wood grain production lines, have a unique manufacturing infrastructure. also have the workshop that equipped with 3 CNC round aluminium extrusionand numerous specific equipment. vast setup is guaranteed to provide an efficient and precise production process meets the various requirements of our clientele.

diverse product range encompasses everything from architectural components home decoration profiles. We cater many different industries and uses. vast portfolio of products will assist you in finding the ideal profile to meet your needs, whether need round aluminium extrusionprofiles or bespoke solutions. With a commitment to quality and innovation constantly expand and enhance our product range in order to meet the needs of changing times of our customers.

1. Cutting: Aluminium extrusion are cut to the length that is needed is a saw. It is critical to ensure that the saw is sharp to prevent damaging the materials.

2. Bending: Aluminium extrusion and Lenwa's standard aluminium extrusions could be bent to your required angle using a bending machine. It is important to follow the manufacturer's instructions when working with a bending machine avoid accidents.

1. Exceptional customer service: Companies that produce round aluminium extrusion should provide excellent customer along with their clients. They should be available to answer any relevant questions provide help when needed.

2. High-quality material: Companies that produce round aluminium extrusion should make sure the materials is of good quality. essential in ensuring that the materials meets the necessary standards regulations.

ONLINE

ONLINE