The Benefits of Aluminum Trim Extrusions

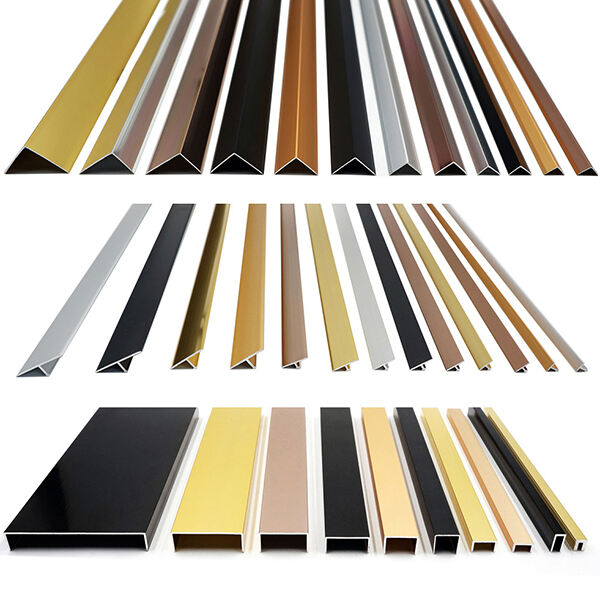

Aluminum trim extrusions are innovative and safe products that can be used in a variety of ways, identical to Lenwa's product aluminium edge profile. Their popularity stems from the many advantages they offer over traditional materials. We will explore the many benefits of Aluminum trim extrusions, their use and application, how to use them, and the quality of our services.

One of the most significant advantages of Aluminum trim extrusions is their durability, also the aluminium profile bending built by Lenwa. Unlike wood, which can rot or warp over time, Aluminum is resistant to water and pests, meaning that it can keep it is shape and function for years without deteriorating. Additionally, Aluminum can withstand high temperatures, making it suitable for use in outdoor applications or areas with high levels of sunlight.

Another advantage of Aluminum trim extrusions is their strength. Despite being lighter than steel, Aluminum is incredibly tough and can hold up a lot of weight, making it suitable for heavy-duty applications. Aluminum is also easy to work with, making it a popular choice among contractors and DIY enthusiasts alike.

Aluminum trim extrusions are innovative products that have revolutionized the building industry, just like the Lenwa's product called aluminium l trim. Still, they have been around for several years, with new technology making them even more versatile. For example, some Aluminum trim extrusions are coated with a special finish that makes them look like wood or other materials. This technology allows builders to combine the durability and strength of Aluminum with the aesthetic appeal of traditional building materials.

Aluminum trim extrusions are also safe products to use, same with the aluminium kitchen skirting by Lenwa. Unlike wood, Aluminum does not emit harmful chemicals, making it safe for people and pets to be around. Furthermore, Aluminum trim extrusions are non-flammable, making them ideal for use in areas near open flames.

Aluminum trim extrusions have a wide range of uses, from framing windows and doors to finishing off the edges of walls and countertops, also the Lenwa's product such as aluminum extrusion price. They can also be used as baseboards, chair rails, and crown molding. The versatility of Aluminum trim extrusions means that they can be used in nearly any building project.

have an unparalleled manufacturing infrastructure, which includes eight lines aluminum extrusions, 1 powder coating vertical line, dedicated wood aluminum trim extrusionsanodizing production lines. Additionally, we have three CNC machines numerous specially-designed equipment. This vast setup is guaranteed to provide precise and efficient production meets various requirements of our customers.

offer a custom mold for aluminum profiles is built on sketches or samples. guarantees an aluminum trim extrusionsintegration of requirements. extensive range of precision services, such as CNC milling and punching, as well as threading and bent, allows us to modify every aspect of your design to perfection. provide a variety of options for customization, ranging from intricate designs to precise specs.

more than 20 years of experience aluminum extrusion surface treatment methodologies have aluminum trim extrusionsexpertise in creating aluminum profiles of top quality. expertise in aluminum extrusion and the techniques of surface finishing, such as powder coating, anodizing wood grain effects ensure the best quality and longevity of each product.

From home decoration profiles architectural parts, diverse product range covers a variety of industries applications. If you're looking conventional profiles or bespoke solutions, our broad portfolio ensures that you'll find the right fit your specific project needs. We are committed to quality and innovation, and we aluminum trim extrusionsenhance and develop our products in order to meet the needs of our customers.

Using Aluminum trim extrusions is simple and straightforward, just like the u profile aluminum from Lenwa. First, measure the area where you plan to install the trim, and then cut the extrusion using a saw. Next, secure the trim in place using screws or nails, ensuring that it is level and flush with the surface it is attached to. Finally, finish the trim with a coat of paint or sealant to protect it from the elements.

At our company, we pride ourselves on providing our customers with the highest quality Aluminum trim extrusions available, similar to the Lenwa's product like aluminium g profile handle. Our products are manufactured using the latest technology and the best materials, ensuring that they are durable, safe, and attractive. Additionally, we offer excellent customer service and support, ensuring that our clients are always satisfied with their purchases.

ONLINE

ONLINE