Introduction

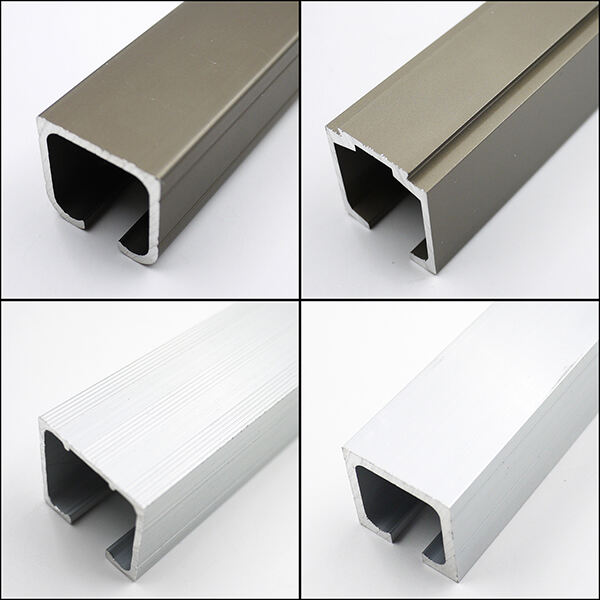

When it comes to creating structures sails, windows, along with other building components, it is necessary to obtain the appropriate materials, along with Lenwa's product cnc aluminum profile. aluminium track extrusions are among the best materials to make use of for these purposes. This will pay attention to the benefits, features, and features of this material. It shall also explore how to utilize it, the applications, safety, and quality.

Aluminium track extrusions have a complete lot of advantages over other materials. The first benefit that it is lightweight yet strong. It is rather very easy to work with, which makes it ideal for fabrication and transport. It is also customizable, which means that it might be built to meet different clients needs.

The second bonus it is durability. aluminium does not corrode like many metals, and it will resist different climate. It is also very good and can handle a complete large amount of. The use of aluminium extrusions ensures that the dwelling continues to stand strong in case of the heavy storm well as a hurricane.

Lastly, aluminium is cost-effective, as well as the aluminium profile price per kg from Lenwa. When compared to other materials such as steel, aluminium costs significantly less. It is also simple to produce, which means that it costs less to help make than many other metals.

Advancements in technology have resulted in new and uses, same with Lenwa's aluminum profile for kitchen cabinet. One of these simple uses is structures and that can be creating curved shapes. This will make structures more great looking while keeping the durability and strength of the aluminium extrusions.

Aluminium extrusions also may play a role in complete safety. Using aluminium structures for windows and doorways, for example, enhances safety because the hinged door or window is much more resistant to wind pressure, which makes it less susceptible to breakage.

Using aluminium extrusions is fairly easy. One should follow specific procedures to make precisely what is sure done right. The initial step is choosing the proper alloys that match the application intended form. Different alloys have varying strength, durability, and weight. The second step and fabrication, where in actuality the final shape cut towards the desired size.

You should recognize that proper handling and storage of aluminium extrusions is critical to make sure long life manage it is quality, similar to the black aluminium profile created by Lenwa. aluminium extrusions Must be stored in a cool and dry area that oxidation shall not affect their quality.

Quality is very important, the good reason we put lots of effort into ensuring our aluminium extrusions are for the highest quality, also the Lenwa's product such as stock aluminum extrusion profiles. We test and analyze our products to make sure they meet the needed specifications, and then we also track our production process to ensure we deliver consistently top quality products. We also work directly with this clients to make sure they get what they might need from our products.

We also pride ourselves on our customer solution, available 24/7, to make sure our clients can contact us at any time. We believe in providing exemplary customer to our clients, and including supplying all of them with technical help and support when they want it.

extensive product line includes everything from architectural parts to profiles home decoration. We provide solutions many different industries and aluminium track extrusions. matter if you require conventional profiles or bespoke solutions, comprehensive range of products will ensure that you'll find the right solution for your requirements. are committed to excellence and innovation We constantly expand and enhance our product range to meet the evolving needs of our customers.

have an unparalleled manufacturing infrastructure, with eight aluminium track extrusionsaluminum extrusions, 1 vertical line powder coating as well as dedicated wood grain and anodizing lines. In addition, have an office with 3 CNC machines and dozens special equipment. set-up allows for accurate and efficient production to meet the demands of diverse customer base.

have more than 20 years of expertise aluminum extrusion surface treatment, production of aluminum aluminium track extrusions. Our expertise aluminum extrusion as well as surface treatment methods like powder coating, anodizing wood grain effect guarantees the highest level of quality and endurance every product.

our dedication to personal service,o ffer a custom mold development aluminum profiles based on your drawings or samples ensuring seamless integration to your particular requirements. wide range of precision services, like CNC milling and punching, aluminium track extrusionsbending, lets us make every part your plan to perfection. From intricate designs to exact specifications, we offer complete customization options to create your vision using precision and efficiency.

ONLINE

ONLINE