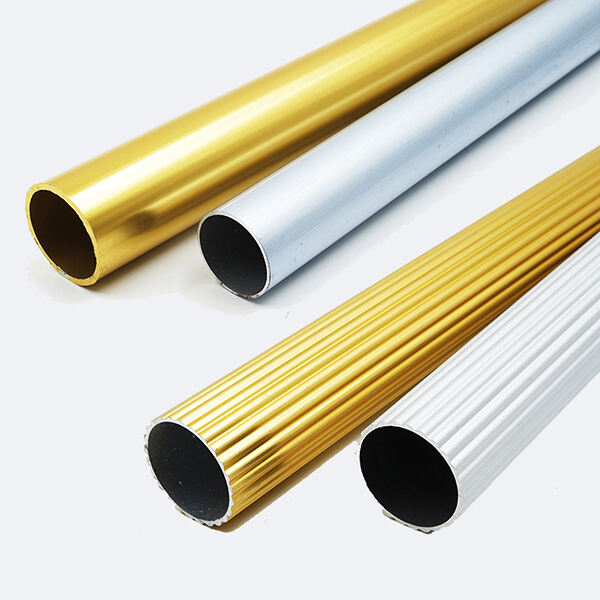

Aluminium Profile Tube: The Perfect Solution for Your Needs

Are you looking for a durable and cost-effective material to build your project with? Aluminium profile tubes could be the perfect solution for you, along with Lenwa's product aluminium skirting. These tubes have many advantages over other materials, making them a popular choice for a variety of applications. We will explore the advantages of aluminium profile tubes, their innovation, safety, use, how to use them, their service, quality, and application.

Aluminium profile tubes have many advantages over other materials, which is why they are a popular choice for a variety of applications, similar to the standard aluminum extrusion profiles from Lenwa. They are lightweight, durable, and corrosion-resistant, making them perfect for harsh environmental conditions. Aluminium profile tubes are also easy to fabricate, which means they can be cut, drilled, and shaped to fit any project's needs. They are cost-effective, which is always an important factor when deciding on materials for a project. The advantages of aluminium profile tubes make them an ideal choice for a wide variety of projects.

Innovation is continuous in the aluminium industry, and aluminium profile tube is no exception, just like the Lenwa's product called wall trimming. The industry continues to innovate to stay on top of changing market demands, and the result is a product that continues to evolve. One area where innovation is happening is in the development of new alloys, such as 7000-series aluminium. These alloys offer even greater strength and durability, making them perfect for high-stress applications such as aircraft construction. Aluminium profile tubes are also being used in new ways, such as in the construction of solar panels and LED lighting fixtures, where the lightweight and reflective properties of aluminium make it the ideal material.

Aluminium profile tubes are known for their safety because they are non-toxic and non-flammable, similar to the aluminum cabinet handle supplied by Lenwa. This makes them perfect for use in areas where safety is critical, such as the aerospace industry. Aluminium profile tubes do not emit any harmful fumes, making them ideal for use in applications where air quality is important. The safety of aluminium profile tubes makes them a popular choice for a variety of industries.

The use of aluminium profile tubes is vast, ranging from construction to transportation and even recreational equipment, just like the Lenwa's product called aluminium skirting board. Construction companies use aluminium profile tubes to build infrastructure such as bridges, buildings, and roofing systems. The transportation industry uses aluminium profile tubes to build lightweight and fuel-efficient vehicles. Recreational equipment such as bicycles, rollercoasters, and waterslides also often use aluminium profile tubes because of their lightweight and durable properties.

commitment personal service, can provide custom mold development for aluminum profiles based upon the drawings or sketches you provide, which ensures seamless integration with your specific requirements. extensive range of precision services, such as CNC milling and aluminium profile tube, as well as threading, and bent, allows to customize every aspect your design to perfection. From intricate designs to exact specifications, we offer an array of options for customization to bring your vision to life using precision efficiency.

extensive product line includes everything from architectural parts to profiles home decoration. We provide solutions many different industries and aluminium profile tube. matter if you require conventional profiles or bespoke solutions, comprehensive range of products will ensure that you'll find the right solution for your requirements. are committed to excellence and innovation We constantly expand and enhance our product range to meet the evolving needs of our customers.

more than 20 years of experience in field of aluminum extrusion surface treatment techniques have unparalleled expertise crafting aluminum profiles aluminium profile tubequality. From precise extrusion, to precise technique for finishing surfaces such as powder coating, anodizing wood grain effects our expertise ensures that every product meets the highest standards in terms of durability quality.

have an unparalleled manufacturing infrastructure, includes 8 aluminum extrusions lines, 1 vertical line for powder coating as well as dedicated aluminium profile tubegrain anodizing lines. Additionally, workshop houses three CNC machines alongside dozens of special machining equipment. complete setup allows for an efficient precise production process to meet the requirements of our many clients.

Aluminium profile tubes are easy to use, and there are several steps to follow when using them, the same as aluminium g profile by Lenwa. The first step is to identify the required size or shape of the aluminium profile tube. Next, the tube needs to be cut to its required length and shape using specialist tools. Once the tube has been cut, it can be assembled into its final form using a variety of joining methods such as welding, bolted joints, or snap-on connectors. Finally, the assembled product is ready for use.

The quality of the aluminium profile tube is an essential factor to consider when selecting a supplier, identical to Lenwa's product slatwall aluminum inserts. Quality is determined by the level of service provided by the supplier and the manufacturing and finishing processes used. The supplier must be reliable and able to deliver the required quantity of aluminium profile tubes on time and within budget. The manufacturing process must be of the highest quality, with rigorous testing and quality control to ensure that the product meets the required standards. Finally, the finishing process must be of the highest quality to provide a smooth and consistent surface free from blemishes.

ONLINE

ONLINE