People seeking resilient, light weight and corrosion proof materials should turn to aluminum pipes. Such Lenwa oval aluminum pipe is widely employed in sectors such as building, automotive and aerospace.

A significant advantage of aluminum tubes is its lighter weight compared to other metals such as steel or copper. This renders it ideal for applications where the quantity of mass is an issue; for example, aircraft or vehicle manufacturing.

Another benefit of using aluminum tubes is that they are resistant to corrosion. Consequently, they are less likely to be destroyed by water or other harmful elements. Besides, Lenwa aluminum pipe needs minimal attention than wood or plastics.

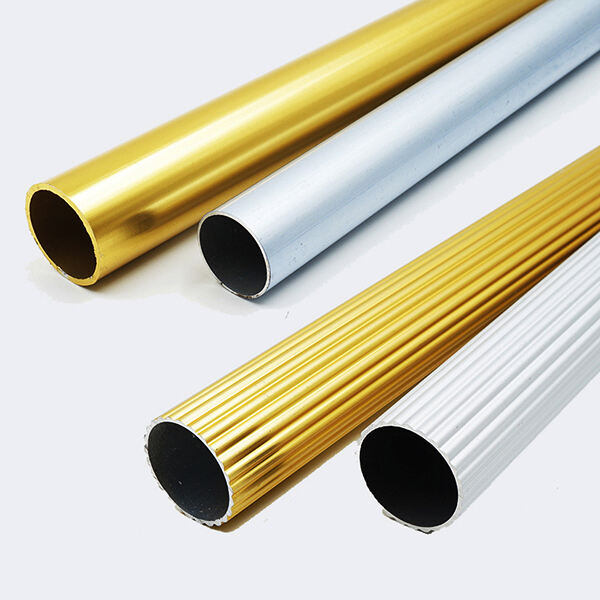

Notably, there have been many innovations in the field of Lenwa profile aluminium prices recently. For instance, some advancements involve the use of new alloys that are stronger and more durable than traditional grades of aluminum. These alloys can be used in a variety of different applications, from construction to aerospace.

The development of new manufacturing techniques has resulted in better precision and accuracy during the production process leading to high quality products as well as reduced lead times among others making sure that there will be no accidents caused by any kind of leakage when using profile aluminum

Aluminum pipes are excellent choices when it comes to safety purposes. It does not produce toxic fumes when heated up like some materials do because it is non-toxic. Furthermore, Lenwa aluminum pipe prices cannot ignite hence safer compared with other alternatives.

Aluminum pipe finds many uses as we have discussed herein. In construction it is frequently used to make scaffolding and for installation HVAC systems. Lenwa 3in aluminum pipe application ranges from engine parts for automobiles and aircraft wings in the automobile industry down to aerospace industry.

With 8 extrusion lines of aluminum a vertical powder coating line well as dedicated anodizing wood grain production lines boast unmatched manufacturing facilities. In addition, our workshop houses three CNC machines as well as a variety of specially-designed machining equipment. complete setup will ensure highest aluminium pipeand efficiency in production and meets varied needs of our customers.

diverse product range encompasses everything from architectural components home decoration profiles. We cater many different industries and uses. vast portfolio of products will assist you in finding the ideal profile to meet your needs, whether need aluminium pipeprofiles or bespoke solutions. With a commitment to quality and innovation constantly expand and enhance our product range in order to meet the needs of changing times of our customers.

have over 20 years experience aluminum extrusion surface treatment manufacturing aluminum profiles. From precise extrusion, precise finish aluminium pipelike anodizing, powder coating, wood grain effects, our expertise ensures every product meets the highest standards in terms of durability and quality.

commitment to personal service, we offer custom mold development aluminum profiles based on the drawings sketches you provide that ensure seamless integration with particular aluminium pipe. vast array of precision services, like CNC milling and punching, as well as threading, and bends, us tailor every element of your design to the highest quality. provide a variety of customization options, from intricate designs precise specs.

When considering the usage of aluminum pipes then this proves quite simple. Firstly, you need to select the correct size and gauge of pipe for your application. After you have selected the appropriate pipe stock, Lenwa aluminum pipe threaded can be shortened by a saw or tube cutter.

Aluminum pipes may also be joined in several ways that include welding, brazing or mechanical couplings. This enables the strongest joints to be formed even though it might require special equipment and training like welding & brazing

The choice of your aluminum pipe supplier should be influenced by a range of factors such as how reliable and efficient their services are and whether they offer quality products. It should look for suppliers who provide a variety of alloys as well as sizes at competitive prices with fast turnaround times.

Also, one needs to choose a dedicated supplier to quality control. For instance, they must put in place stringent tests and inspection processes to ensure that their products are up to standard.

As already stated, aluminum pipe is employed in diverse sectors of the economy. It is very common in construction to be used for scaffolding, HVAC systems as well as plumbing. For automotive industries, Lenwa aluminum pipe bending are widely used in making engine components and exhaust systems.

In the aerospace industry, aluminum pipes are used for numerous things ranging from aircraft wings to fuel tanks. Aluminum offers an excellent choice for aerospace applications on account of its lightness and resistance to rusting.

aluminum pipe can be a good choice of material due to its versatility and durability hence can be used in many different ways. Having several advantages and innovations makes this material a great option when searching for dependable quality; hence it can be put into use by anyone. Opting for a dedicated provider to quality service means satisfaction for your aluminum tubing’s needs with the best possible products and support being offered.

ONLINE

ONLINE