Surface treatment refers to the process which an underlying material is mechanically, chemically or electrochemically changed on its surface. Surface treatment is an integral part of the finishing process, used to protect and ensure durability as well as corrosion resistance in aluminum products. This is very useful in industries like automotive, aerospace, construction and electronics having wide applications of aluminum products.

Significance of Surface Treatment for Aluminum Products

Advantages of Surface treatment for Aluminum Products:SIndArtificially Controlled|-- Aluminum Profile Factory

Resistance to Corrosion: This protective coating helps prevent aluminum goods from succumbing to corrosion, a factor that might stem as easily saltwater or moisture in the air (if environmental shock).

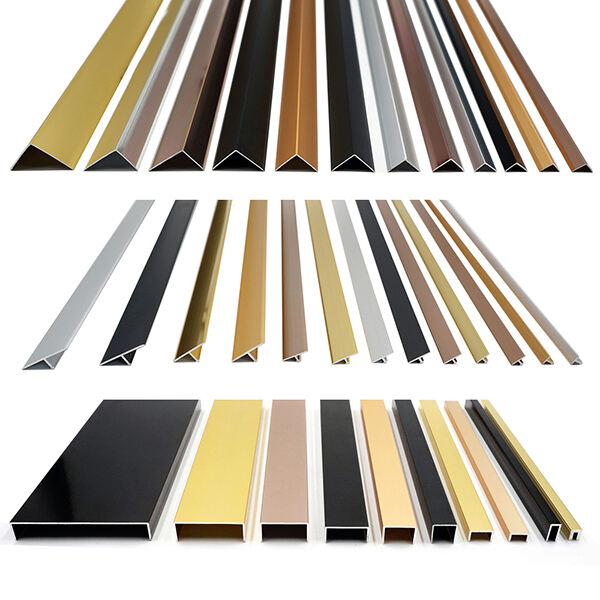

Improved Aesthetics: Surface treatments help to improve the beauty and appearance of aluminum products by imparting a polished, shiny or textured finish.

Increased Lifespan: With surface treatments, aluminum products can have a longer life as they are more scratch and impact-resistant.

Less Maintenance: Effective surface treatment decreases the maintenance of aluminum products, reducing time and money spent on it in due course.

An Overview of Various Surface Treatments for Aluminum Products

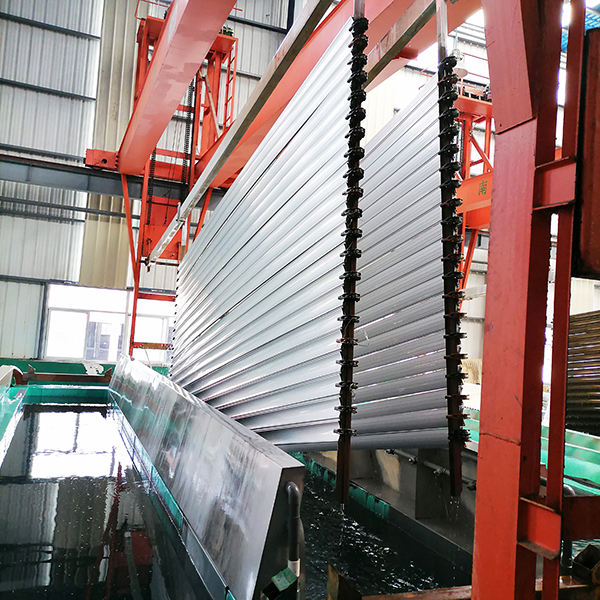

Anodized aluminum products: In this electrochemical process an oxide layer is formed on the surface of aluminium which makes it resistant to corrosion, wear and tear as well as prevents UV rays from having their effect.

Powder Coating: One option is to give aluminium items a dry powder coating before heating them up so it solidifies and becomes resilient, but also aesthetically pleasing. There are a range of finishes and opacities, gloss levels available for powder coating.

Electroplating - to improve the durability and corrosion resistance of products by providing an aluminum component with a coating made up of very thin layer(s) on them, typically nickel or chromium.

Decorative Finishing -Polishing- Destroys the top most layer of Aluminum, however produces a shiny reflection if a mirror finish is desired and can be used to eliminate surface bourdeaux.

Painting serves as a surface treatment method where aluminum products are coated with paint to improve the appeal and make it Corrosion resistant.

Organic Coating: Process that imparts increased corrosion resistance to aluminium products and makes them amenable for painting or adhesive bonding by depositing a thin oxide film on the surface of the product.

Metalizing: Thermal Spraying using a process that sprays molten metal, ceramic or polymer particles onto an aluminum surface to create a durable and corrosion-resilient coat. "

The Proper Surface Treatment Application And Quality Assurance Of Aluminum Objects

Aluminium Surface treatment needs experienced and skilled professionals who have knowledge of the entire process. Methods of application will depend on the type of surface treatment used, and to some extent product being treated as well. Manufacturers and consumers alike must follow proper safety regulations and wear protective gear including gloves, masks, eyewear when working with surface treatment chemicals.

Increasing Role of Surface Treatment in Diverse Industries

An increasingly broad range of industries are engaging in surface treatment applications, including aerospace and automotive, construction materials and electronics. Surface treatment companies offer a wide selection of services that include everything from design, production to installation. Process accreditations, such as ISO9001, ISO14001 and AS9100C are essential to confirm surface treatment processes meet corresponding environmental and quality regulations

So, fundamentally speaking the use of surface treatment on aluminum products is his initial production process which increases its corrosion resistance more than that extends also to increase dullness in appearance. Great final metal finishes include anodizing, powder coating, electroplating, polishing, painting or clear chemical conversion film finishing and thermal spraying. Both the manufacturers and consumers must follow safety precautions for surface treatment chemicals that include wearing necessary protective gear. Facing a wide range of trouble, companies that offer the service to treat surfaces are doing just as important work; after all, impeccable quality has severe competition with environmental and quality standards.

EN

EN

ONLINE

ONLINE