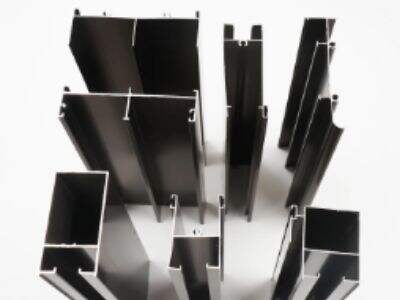

Aluminum profile is an essential part of CNC processing. Typically, they contribute to a variety of products that we encounter daily: components for vehicles, components for aircraft, as well as several items in our houses: furniture and devices. Selecting the one that fits to be used in CNC Machining as an aluminum is a key factor, when getting into this field. This decision can have a huge impact on the final product quality. A great decision will give us a product with good quality and works duly.

Aluminum Profiles: Why They Are CNC Machining Friendly

Aluminum Profile are light-weighted and easy to work with, which is another reason why they are used frequently in CNC machines. This is a huge benefit, as it allows for easier production of detailed components and complex geometries required by manufacturing machines. CNC machines are special tools that cut aluminum profiles into unique shapes and sizes. Such patterns which require precision and intricacy to create are often hard to achieve by hand.

Aluminum profiles easy to work with and quite robust. If you work in harsh environments, they will last long time for instance, aluminum profiles are durable and this means that products made of aluminum profiles will not break or wear out easily. Due to the ability of aluminum profiles to be cut, bent and welded into virtually limitless shapes they are excellent for custom machine builds. Not only can it be near limitless in its raw design; but that versatility means that manufacturers can deliver nearly any type of product.

Selecting the Appropriate Material for CNC Projects

Choosing the correct material is possibly the first thing you have to do when working on a CNC project. extruded aluminum profiles provide the great benefits for many people are using at projects compared to other materials. One of the great advantages is that we can work with lightweight aluminum profiles, which is essential for low weight projects. For instance, in aerospace applications, enabling lighter components may mean airplanes that can fly better.

But selecting the appropriate material can be difficult. The wrong material means major problems in the end product. Picking the wrong one may lead to an ill-fitting, poorly-functioning, or even weak product. Which make it important to determine the material before any CNC work done.

The Importance of Aluminum Profiles on How to Make Machines Work Better

All manufacturers want their machines to run as well as they can. The best way to do this is through choosing the correct materials for their CNC projects. The performance efficiency and accuracy of CNC machines can be enhanced by using high standards aluminum profiles manufacturing. Such improvement can help minimize production costs that is, the cost involved in making more products gets lower than before.

Aluminum profiles are produced by advanced technology that gives out precise Quality Finish and dimension. This technology assists makers in confirming that the aluminum profiles are robust and accurate. Sturdy aluminum profiles make it possible to build high-end products with confidence and longevity.

How to Choose the Best Aluminum Profiles for Custom Machines

Replacing custom machines with a new machine is impossible, even if it aids efficient manufacturing. Here choosing correct aluminum profiles play an integral process. Aluminum profile matters the most in final product whether it strong, accurate and looks good. Its tip: When selecting an aluminum profile, consider to how you would cut that, drilling on the profile and in case you need to weld it Such processes are critical to making sure that the product is in accordance with the client needs/requirements.

Various custom machines can also require various types of aluminum profile cnc depending on numerous applications. Some profiles were objective to strength, others intended for flexibility. Depending on your product use case and budget for the project, selection methodology ought to be considered. These decisions will lead to the more likely chance of success, provided manufacturers keep these factors in mind.

Best Aluminum Profiles for CNC Projects and Discovering

In order to find the right aluminum profiles for your CNC projects you have to know what every project actually requires. aluminum profiles have various characteristics that can make them ideal for some projects, and impractical for others. For example, certain profiles are more suitable for light-weight applications while others are meant for rugged-operations.

Considering the entire production process is equally important when it comes to choosing the right aluminum profile. This involves the manufacturing of the profiles, costs and what does he want exactly (as in which profiles). One such company, Lenwa, provides a number of high-quality aluminum profiles for custom machining and CNC services. This gives a wide range of options to the clients for traceability of their projects and making easy accessibility.

In the end, selecting a suitable aluminum profile for CNC machining has some critical impact on the quality of a final product. Having the right material is crucial to a successful CNC machining process that allows manufacturers to develop high-quality components while cutting on costs and improving production. With high-quality aluminum profiles offered by companies like Lenwa, overall CNC machine efficiency can be significantly enhanced. Because of this, aluminum profiles are versatile for many general applications including in custom machines. When choosing an aluminum profile, it is important for manufacturers to consider how the profile will be used, whether or not their actual budget can accommodate the material as well various other factors that can influence the success of any given project. This allows them to make informed, data-driven decisions that are sure to yield higher-quality results.

EN

EN

ONLINE

ONLINE