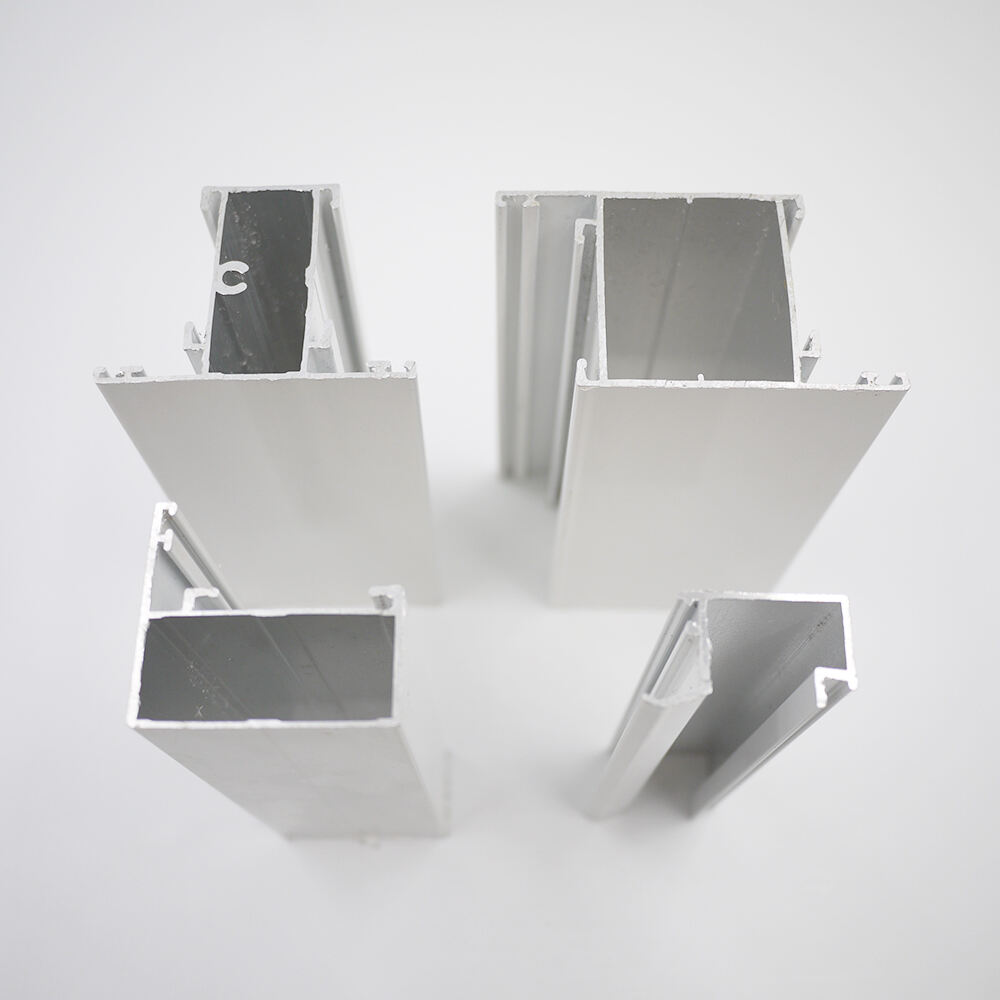

Explore the Unlimited Applications of Custom Standard Aluminum Extrusion Profiles

Aluminum shapes, or more commonly known as standard extruded aluminum profiles are an excellent choice for your building projects! Appearing in different sizes, shapes and influencing factors have matted them using the aluminum punches via a machine making everything cohering on vast or dumpy surfaces respectively.

High strength is one of the star attributes of traditional extruded aluminum profiles. They boast a impressive load bearing capacity and can endure immense stress which makes them perfect for all kinds of constructions, from fences and railings to aircraft. Further, these profiles on display superior resistance to corrosion and other forms of wear brought about by both weather elements as well chemicals assuring their performance over an extended lifetime.

A lot of exciting (and very technologically advanced) changes have been made to the current extrusion process for standard aluminum beams. There, we have some profiles with thinner walls but still able to carry the same load and as a result our parts are now lighter and easier for handling. At the same time, some profiles can now be curved which makes them perfect for a wider range of design needs.

Due to their structural sound nature, standard Extruded Aluminium Profiles are safer to work with. Their strength causes them to be largely indestructible, even under tough handling conditions. As such, these profiles are dependable for use in safety-related applications including playground equipment, safety barriers and fire escapes etc., where their high heat resistance is invaluable.

What are the Standard Extruded Aluminum Profiles Used For

Their usage allows for an incredibly wide range of potential applications, thanks to the sheer versatility that a standard extruded aluminum profile can provide. They could be used to create carports, greenhouses, window frames and curtain walls among others. These profiles are used in industrial contexts for building things like conveyor belts and safety guards, so a wide range of manufacturing needs. The possibilities for things created with standard extruded aluminum profiles are endless, as they come in so many different shapes and sizes.

More Optimal Use of Off-The-Shelf Extruded Aluminium Profiles

A must to exploit the potential of standard extruded aluminum profiles is that you should opt for a particular type as necessary by your project.Parameter 1: Material Differences Precise measurements are critical to the appropriate size and shape for use in supporting that intended load. Consequently cutting the profiles into suitable dimensions, drilling or tapping holes for fasteners and assembling them according to standards are crucial in construction phases. For safety, be sure to follow directions and wear appropriate personal protective equipment like gloves or eye protection.

Make sure you are working with a supplier who provides good services and high-quality products in mind whenever purchasing generic extruded aluminum profiles. Look for verified-safe-and-tested profiles that come with a warranty or guarantee In cases where there is doubt about which profiles to select, consult experts or perform the basic common-sense research that has not been done in this case.

our dedication to personal service,o ffer a custom mold development aluminum profiles based on your drawings or samples ensuring seamless integration to your particular requirements. wide range of precision services, like CNC milling and punching, standard extruded aluminum profilesbending, lets us make every part your plan to perfection. From intricate designs to exact specifications, we offer complete customization options to create your vision using precision and efficiency.

wide range of products includes everything architectural components to decorative profiles homes. We serve a wide range of different industries applications. Our extensive portfolio can assist you in finding the ideal profile for your project, whether you need standard profiles or custom solutions. are standard extruded aluminum profilesquality and innovation we constantly increase and enhance our product range in order to meet the needs changing times of our customers.

have an unparalleled manufacturing infrastructure, includes 8 aluminum extrusions lines, 1 vertical line for powder coating as well as dedicated standard extruded aluminum profilesgrain anodizing lines. Additionally, workshop houses three CNC machines alongside dozens of special machining equipment. complete setup allows for an efficient precise production process to meet the requirements of our many clients.

With over 20 years experience in the field aluminum extrusion and surface treatment standard extruded aluminum profileshave unmatched proficiency in the creation of aluminum profiles high-quality. From precise extrusion to meticulous surface finishing techniques such as powder coating, anodizing wood grain effects, our experience ensures that each product meets the highest standards in terms of durability and quality.

Application of mixed aluminum volumes varies from industries to manufacturing, transportation and construction. In construction, these profiles are used for facades, glazing and interior partitions; in transport they help build strong vehicles such as airplanes or train carriages. Also the manufacturing sector takes great benefit from standard Aluminium extrusion profile because of its exceptional qualities that allow for creating conveyor belts, packaging lines and safety barriers in factories. No matter, you starting a new construction project; automotive repair or industrial machinery manufacturing the extruded aluminum profile is an excellent option to create long-lasting and durable structures.

ONLINE

ONLINE