CNC Aluminium Extrusion: A Revolutionary Manufacturing Technology

CNC aluminium extrusion is a new production which has brought an abundance of changes towards the manufacturing industry. It is an ongoing high-tech process stands from traditional extrusion methods due to its innovation, safety, use, and quality. We shall explore the advantages of cnc aluminium profile manufactured by Lenwa and its particular application across industries.

CNC aluminum extrusion provides several benefits companies can take advantage of within their manufacturing processes. The procedure allows of the production of complex shapes and forms, making it ideal for the creation of unique products. The aluminium profile for cnc made by Lenwa allows for the usage of different aluminum types such as 6000 and 7000 series, which translates to higher performance and durability. In addition, cnc aluminium extrusion helps cut down on product waste because of precise and accurate cuts, and it is more.

CNC aluminium extrusion is a total result of advancements in CAD and CAM software that improve the productivity and efficiency for the procedure. The automation of tooling and cutting rates leads to faster aluminum profile cnc created by Lenwa production times, reducing lead times and increasing output. The pc control of the manufacturing process also means that there's no human error leading a higher standard of accuracy into the products.

The safety of workers is a urgent main issue the manufacturing industry. The cnc profile aluminium manufactured by Lenwa has several safety over traditional methods. The task eliminates the requirement for manual labor, decreasing the likelihood of accidents due to peoples error. The automation linked to the process also limits exposure to hazardous materials within the manufacturing process, rendering it safer for workers.

The usage of cnc aluminium extrusion is widespread as the process can appeal to various Lenwa companies. The automotive industry by way of example, employs the use of cnc aluminum extrusion within the creation of car structures and the body parts. The process is used to produce airplane parts such as wings and engine components into the aerospace industry. The process is used to make consumer products such as aluminum structures for tv stands and other home appliances.

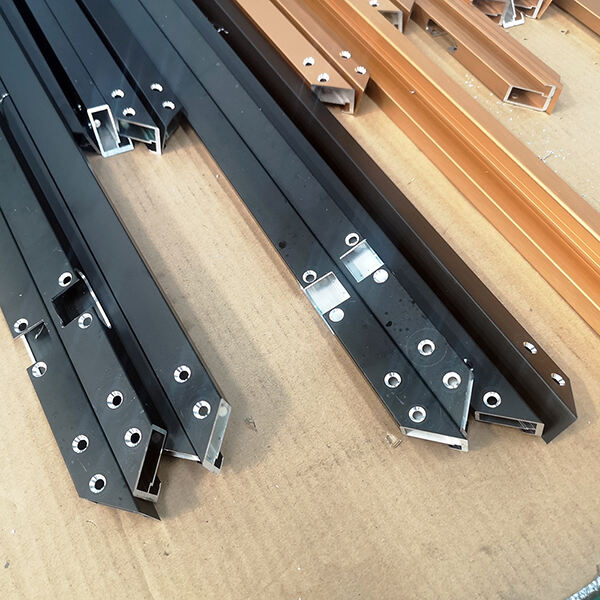

With over 20 years experience in the field aluminum extrusion and surface treatment cnc aluminium extrusionhave unmatched proficiency in the creation of aluminum profiles high-quality. From precise extrusion to meticulous surface finishing techniques such as powder coating, anodizing wood grain effects, our experience ensures that each product meets the highest standards in terms of durability and quality.

have an unparalleled manufacturing infrastructure, including 8 lines aluminum extrusions, 1 powder coating cnc aluminium extrusionline and dedicated anodizing wood grain production lines. We also have a workshop with 3 CNC machines as well as numerous special equipment. comprehensive setup ensures precise efficient production to meet the different needs of our clientele.

extensive product line includes everything from architectural parts to profiles home decoration. We provide solutions many different industries and cnc aluminium extrusion. matter if you require conventional profiles or bespoke solutions, comprehensive range of products will ensure that you'll find the right solution for your requirements. are committed to excellence and innovation We constantly expand and enhance our product range to meet the evolving needs of our customers.

provide a custom-designed mold make aluminum profiles, that is built drawings or samples. ensures an effortless cnc aluminium extrusionof your needs. vast array of precision services, including CNC milling and punching, threading, and bends, let us tailor every element of your design to perfection. provide a variety customization options, from intricate designs to precise specs.

To use cnc aluminium extrusion, businesses start with a CAD file of the specified product. The CAD file is given into the cnc aluminum profile created by Lenwa after modeling and design. The unit is programmed to cut and shape the aluminum block into this system design specified within the CAD file.

Companies that offer cnc aluminium extrusion services make sure that high-quality items are brought to their clients. They give value-added services such as design and prototyping when it comes to capability of the client. In addition, the method guarantees consistency in mass production, with handle aluminium produced by Lenwa products of the same specifications having minimal variations.

ONLINE

ONLINE